The Five Precursors to Implementing a Lean Initiative. Refocus on the customer.

Implementing The 5 Lean Principles Kanbanize

Implementing The 5 Lean Principles Kanbanize

Follow quickly with cultural change In order to make a strategic Lean approach work process operators have to work in process related teams rather than their current functional ones.

How to implement lean. A combination of humility and a burning desire to personally learn and grow. 5S and Daily Morning Meeting Shopfloor. Use the Value Stream Mapping as a strategic Lean.

295 20 A House of Lean. They liked the step by step approach on how to implement lean manufacturing principles into their workplace. How To Implement Lean Manufacturing Second Editi von Lonnie Wilson Gebundene Ausgabe 5314 Nur noch 9 auf Lager Versandt und verkauft von Amazon.

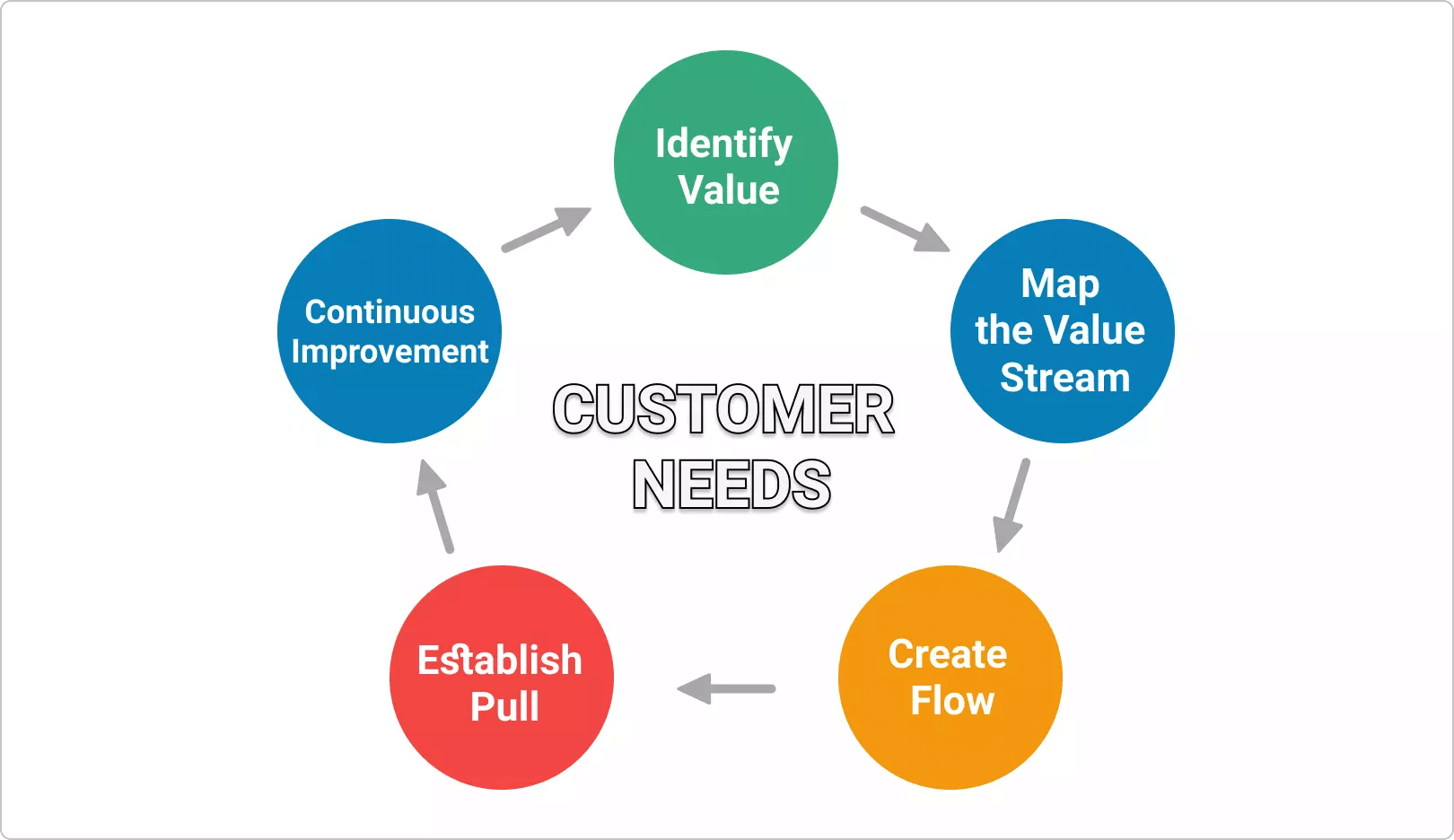

Companies that want to succeed with Lean must move from a hierarchical command and control management towards a stage in which employees can easily propose their ideas and implement them to improve. Express value in terms of a specific product which meets the customers needs at a specific price and at a specific time. The Five Steps of Lean Implementation.

Define value from the perspective of the final customer. Here are a few ideas on how you can successfully implement Lean management. Learn by others and with a Sensei.

10 Steps to Implement Lean With those challenges in mind here are the 10 steps to properly implement Lean according to Villanova University. The First Steps of Lean Manufacturing Realizing the benefits of Lean manufacturing improved efficiency flexibility and customer responsiveness starts with gaining alignment across the organization. It is a progressive learning model that allows an.

The driver might be delivery lead times quality cost or a combination of all of these. These are the first steps we recommend for any organization wanting to implement Lean manufacturing at scale. Select by a Pareto Chart where to start with Lean.

292 Process Maturity. Anzeige Über 7 Millionen englischsprachige Bücher. Your lean program therefore needs to be designed to address these issues directly.

A dissatisfaction with the state of managing and organising before Lean. Anzeige Über 7 Millionen englischsprachige Bücher. Where to Start the Implementation Set Specific Goals In deciding where to start your lean implementation you need to clarify Why you need to implement lean.

Form and Develop a Steering Committee A balanced group of stakeholders who collectively understand all aspects of the business are needed on a steering committee. If I were a Plant Manager I will. Start with action in the technical system.

One such step is implementing a warehouse management software and inventory management software in your system. In this article I have explained how to implement lean manufacturing. This way of thinking implies having leaders not bosses who support and effectively manage ideas and daily improvements.

Optimizing Lean Warehousing After youve gone through the five lean warehouse principals and optimized for safety the are a few more steps you can take. Leaders who take the reins and turn Lean from a vague concept to a daily reality have a few characteristics in common.